The subsurface data experts meet the leading innovator in borehole steering technology — offering clients the most effective, cutting-edge solutions that save time and money. Combined, Wireless Services Group and Aziwell offer the best expertise, knowledge, hardware and software to enhance productivity, safety and environmental friendliness in mining, exploration and civil engineering downhole operations.

AZIDRILL®

The AZIDRILL® is a revolution in borehole steering, providing a core sample closer to the industry standards in wireline diamond drilling while steering boreholes. The tool comprises a range of innovations, making it highly beneficial for a broad range of exploration and civil engineering projects.

Advantages of borehole steering technology using AZIDRILL®:

- Collects the largest directional core sample in the world and thus increases geological information

- Fast and easy borehole steering with precise targeting and multi-branch boreholes

- Oriented core samples while drilling.

- Reduce environmental footprint through reduced drill pads, operational time and CO2 emissions.

- Similar drilling rate as standard diamond drilling.

- Similar drilling parameters and water consumption as standard diamond drilling.

- No depth limitations.

- Operate with ease. No special pumps, rods or rigs needed.

The AZIDRILL® directional core barrel provides an efficient way to steer your bore holes straight to target while cutting core. Hit your targets at first try, make multiple branches from one borehole, reach of otherwise impossible areas, or control horizontal holes with a pre-determined path right on the target.

AZIDRILL® N-size

Cuts an N-size borehole while collecting BTK-size core samples.

Weight: 65kg (143 lbs)

Diameter: 71mm (2.80”)

Length: 4.3m (14 ft)

Bit diameter: N – 75.3mm (2.97”)

Reamer diameter: N – 75.7mm (2.98”)

Core diameter: BTK – 40.7mm (1.60”)

Core length: 3m (10ft)

Running gear: N/N2/N3/NU

Pressure: 20 bar (290 psi)

Flow: 25-50 L/min

Circulation fluid: Water

Additives: Optional

RPM, typical: 700-1000

Feed force, max: 5000kg (11022 psi)

Feed force, typical: 2500kg (5511 psi)

Dogleg, typical: 5 – 10 (° per 30m/100ft)

Max depth: N rod max

AZIDRILL® H-size

Cuts an H-size borehole while collecting N2-size core samples.

Weight: 85kg (187 lbs)

Diameter: 90mm (3.54”)

Length: 4.3m (14 ft)

Bit diameter: H – 95.6mm (3.76”)

Reamer diameter: H – 96.1mm (3.78”)

Core diameter: N2 – 50.7mm (2.00”)

Core length: 3m (10ft)

Running gear: H/H3/HU

Pressure: 20 bar (290 psi)

Flow: 50-70 L/min

Circulation fluid: Water

Additives: Optional

RPM, typical: 600-800

Feed force, max: 7500kg (16533 psi)

Feed force, typical: 3500kg (7715 psi)

Dogleg, typical: 4 – 8 (° per 30m/100ft)

Max depth: H rod max

GEORAPTOR®

The GEORAPTOR® marks a new era in borehole steering by streamlining the way to steer boreholes quickly back on target and multi-branch boreholes, while eliminating the need for steel wedges and mud motors. GEORAPTOR® enables drilling contractors to perform directional drilling independently due to its unique design and user friendliness. The tool goes straight on the drill rods and is powered by the rotation and feed pressure supplied by the rig. This also means no extra rods or pumps are required compared to running mud motors. The threshold for performing directional drilling has NEVER been lower.

Advantages of borehole steering technology using GEORAPTOR®:

- Steer any borehole fast and easy with precise targeting and multi-branch boreholes.

- Does not require third party field engineers.

- Reduce environmental footprint through reduced drill pads, operational time and CO2 emissions.

- Eliminate the use of steel wedging and mud motors.

- No depth limitations.

- Operate with ease. No special pumps, rods or rigs needed.

The GEORAPTOR® directional barrel provides an efficient way to steer your boreholes straight to target. Hit your targets at first try, make multiple branches from one borehole, reach of otherwise impossible areas, or make horizontal holes with a pre-determined path right on the target. All above can easily be achieved without the requirement of third party field engineers on site.

Show your interest today and you will be prioritized once the tool becomes commercially available!

Save time & money

Time and cost savings on exploration drill sites using GEORAPTOR® are typically 20 – 50% compared to only utilizing standard conventional drilling with or without traditional steering methods such as wedging og mud motors.

With directional drilling, you can achieve the following:

- Reduced operation time

- Reduced number of meters drilled

- Reduced total cost of project

- Reduce the number of drill pads required to reach your targets

- Reduce water consumption and CO2 emissions

Weight: 20kg (44 lbs)

Diameter: 71mm (2.80”)

Length: 1m (3.3 ft)

Bit diameter: N – 75.3mm (2.97”)

Reamer diameter: N – 75.7mm (2.98”)

Running gear: N/N2/N3/NU

Pressure: 20 bar (290 psi)

Flow: 40-60 L/min

Circulation fluid: Water

Additives: Optional

RPM, typical: 700 – 1200

Feed force, max: 5000kg (11022 psi)

Feed force, typical: 2500kg (5511 psi)

Dogleg, typical: 5 – 10 (° per 30m/100ft)

Max depth: N rod max

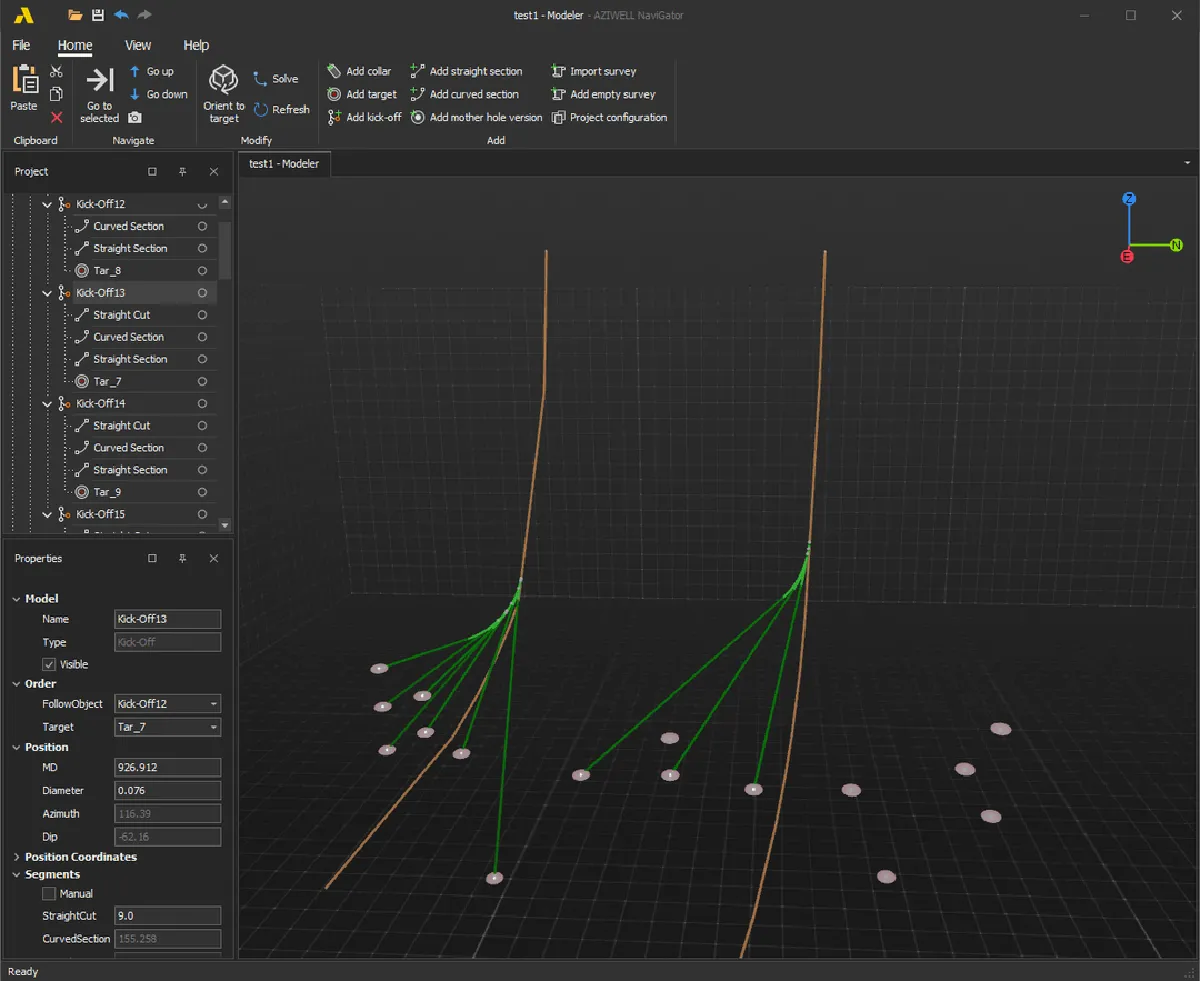

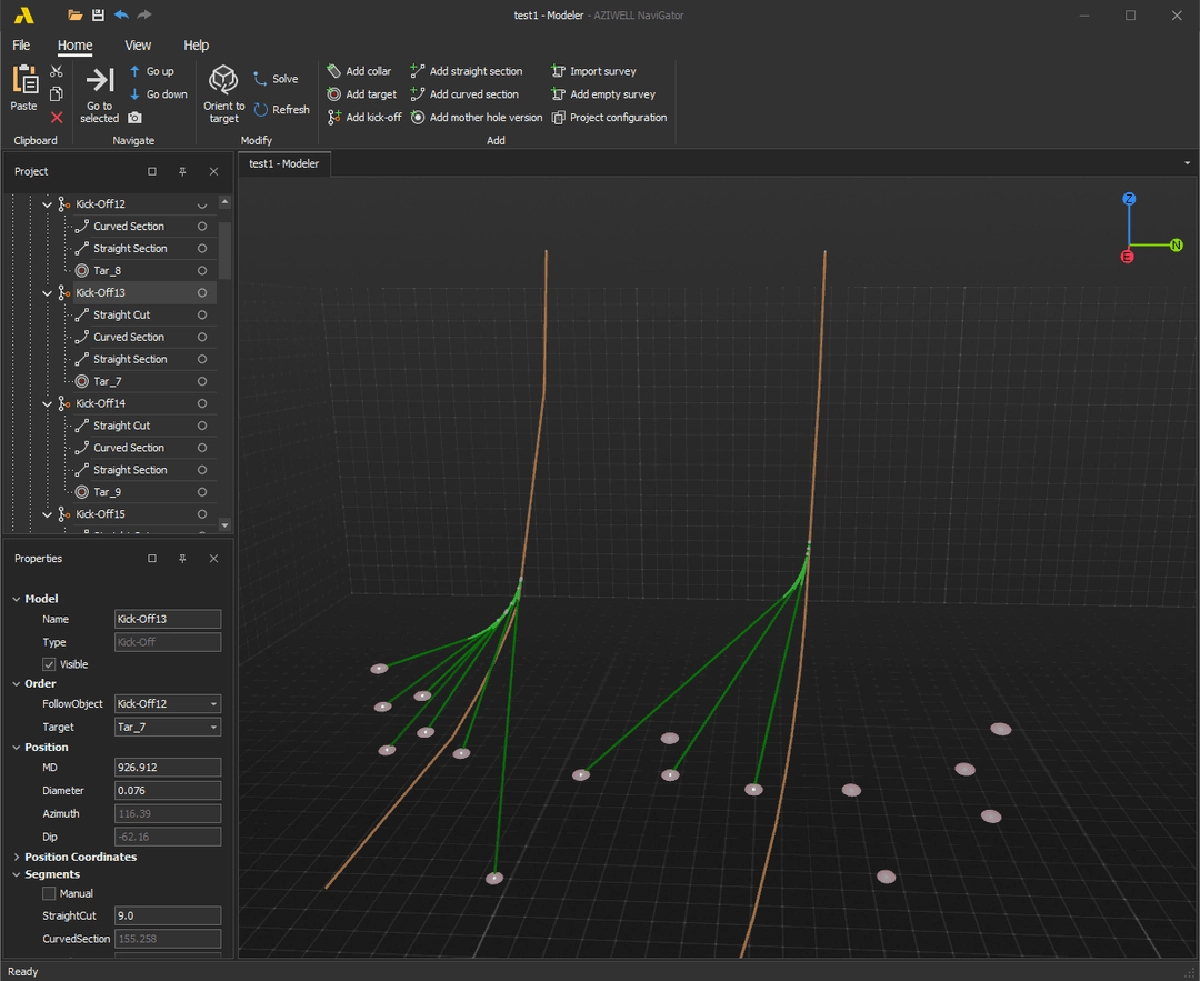

The NAVIGATOR software is the leading application for borehole planning and survey data management enabling engineers and geologists to plan and optimize well paths. NAVIGATOR provides fast, easy and better hole planning, whether the task is simple or complex. Plan for large exploration projects efficiently and generate drill reports as the boreholes progress while improving QA/QC.